- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

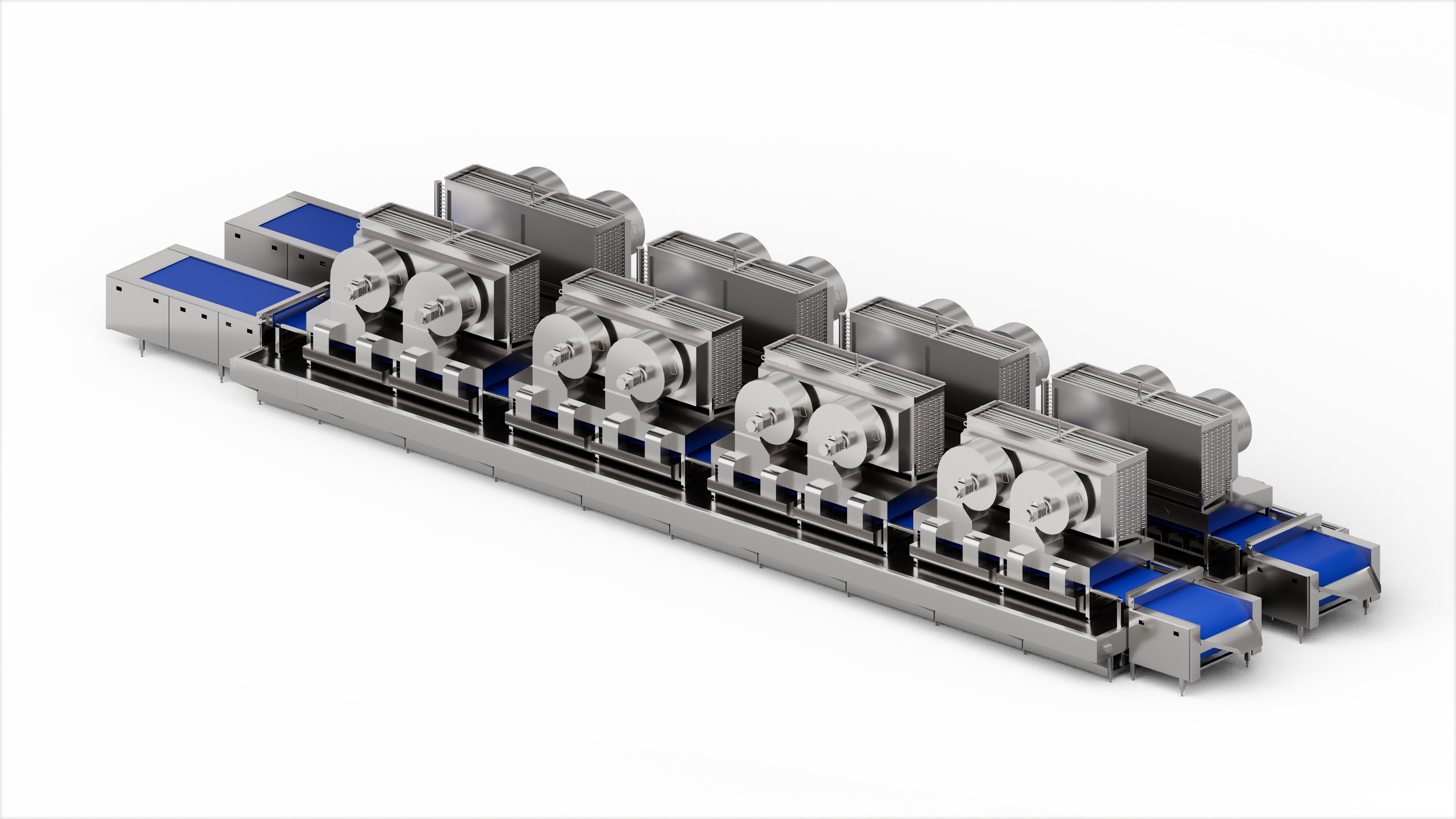

Wolfking impingement tunnel freezer uses high velocity jets of air to directly blow at the top and bottom surfaces of product, and quickly reduce the outer temperature. Impingement cold air-jets remove the static surface boundary layer that surrounds the product resulting in a very fast freezing, small ice crystals and thus high product quality, minimizing dehydration loss.

It applies to products with a high surface area-to-weight ratio and ideally freeze shrimp, fish and other flat products, minimizes cellular damage, improves yield and increases shelf life to enhance food quality.

Performance

●Lower energy consumption: the fastest and most cost-efficient way to freeze delicate, thin products

●Maximum yield with minimal DEHYDRATION LESS.

Evaporator and fan

●Evaporator construction optimizes air velocity and maximizes heat transfer and performance.

●Optimized air velocity through the evaporator, maximizing heat transfer, frost pick-up and performance.

Hygiene

●Stainless steel belt, main structure and panels, to eliminate risk of bacteria build-up.

●Easy, effective cleaning, satisfying the highest food safety requirements.

●Elevated construction ensures effective cleaning around and beneath the machine.

Modular design and flexibility

●Modular design makes it quick and easy to expand your production capacity as your customer demand grows.

●Single or double-belt alternatives, with variable belt speeds and directional controls, ensure maximum processing flexibility.

●Available to pre-assembled in our factory prior to shipping, ensures high quality manufacturing and short on-site installation.

Reliability

●KTK stainless steel mesh belt

●Single or double-belt alternatives, with variable belt speeds and directional controls, ensure maximum.

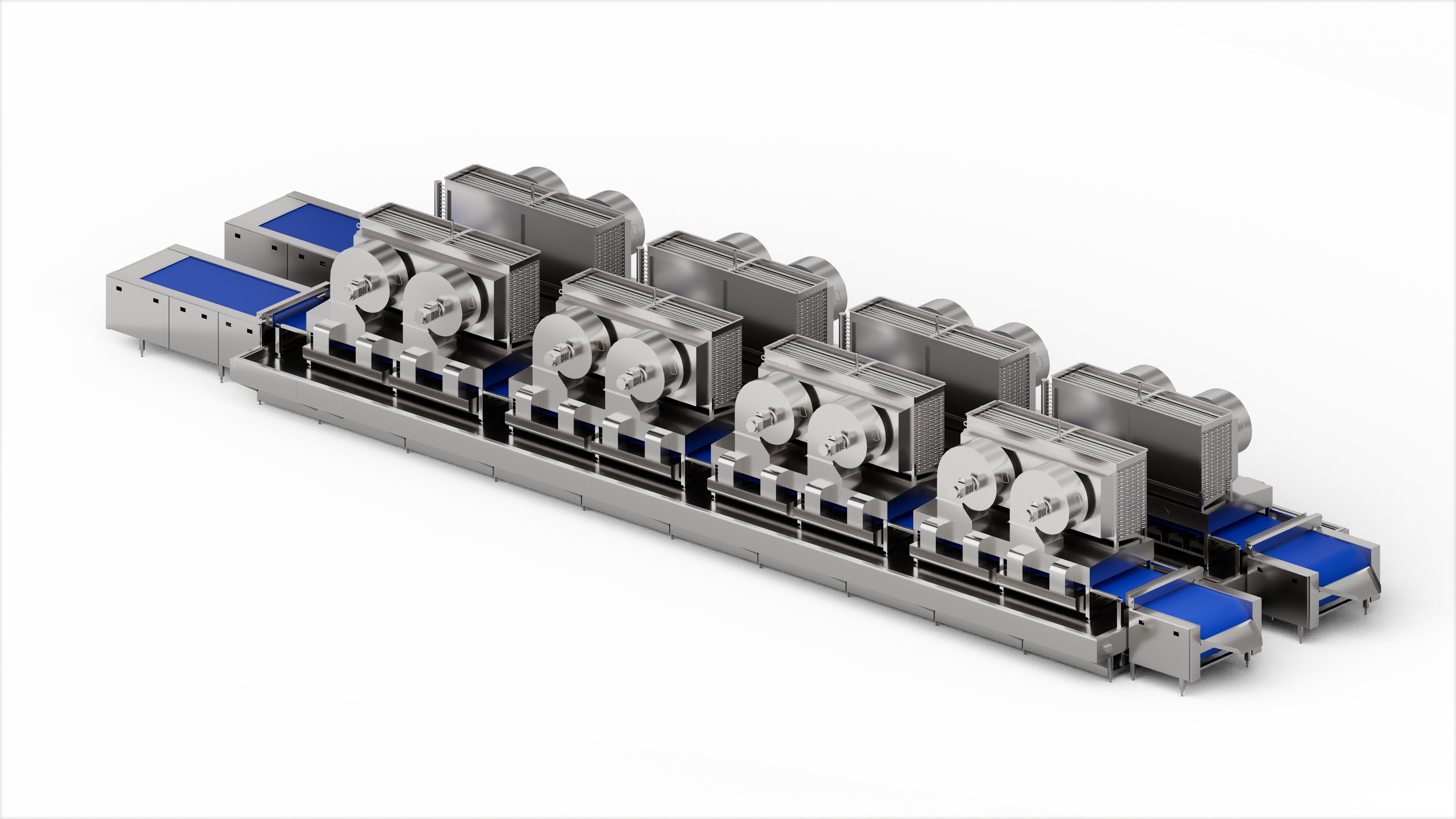

Wolfking impingement tunnel freezer uses high velocity jets of air to directly blow at the top and bottom surfaces of product, and quickly reduce the outer temperature. Impingement cold air-jets remove the static surface boundary layer that surrounds the product resulting in a very fast freezing, small ice crystals and thus high product quality, minimizing dehydration loss.

It applies to products with a high surface area-to-weight ratio and ideally freeze shrimp, fish and other flat products, minimizes cellular damage, improves yield and increases shelf life to enhance food quality.

Performance

●Lower energy consumption: the fastest and most cost-efficient way to freeze delicate, thin products

●Maximum yield with minimal DEHYDRATION LESS.

Evaporator and fan

●Evaporator construction optimizes air velocity and maximizes heat transfer and performance.

●Optimized air velocity through the evaporator, maximizing heat transfer, frost pick-up and performance.

Hygiene

●Stainless steel belt, main structure and panels, to eliminate risk of bacteria build-up.

●Easy, effective cleaning, satisfying the highest food safety requirements.

●Elevated construction ensures effective cleaning around and beneath the machine.

Modular design and flexibility

●Modular design makes it quick and easy to expand your production capacity as your customer demand grows.

●Single or double-belt alternatives, with variable belt speeds and directional controls, ensure maximum processing flexibility.

●Available to pre-assembled in our factory prior to shipping, ensures high quality manufacturing and short on-site installation.

Reliability

●KTK stainless steel mesh belt

●Single or double-belt alternatives, with variable belt speeds and directional controls, ensure maximum.