- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

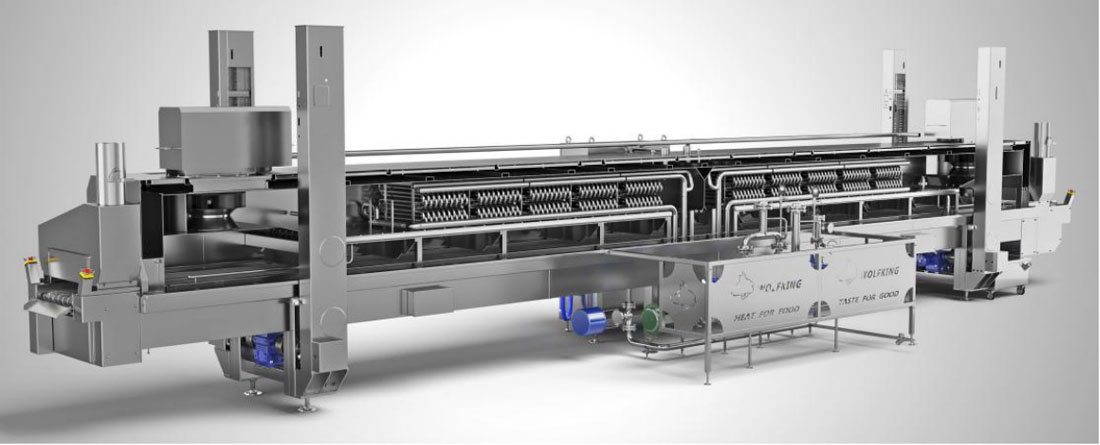

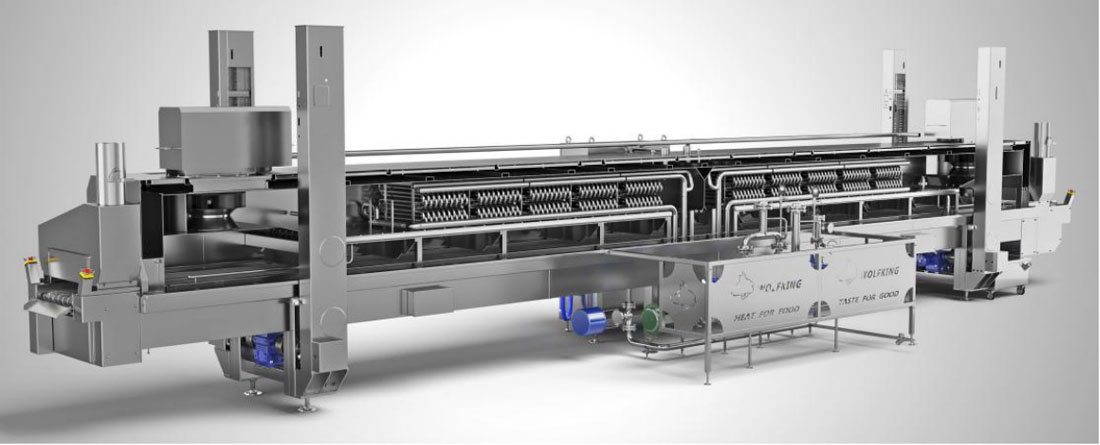

With our oven steam cooker, you can produce steamed, cooked and roasted products with a high yield and attractive appearance. Uniformity, versatility simplicity and reliability come together while cooking with our oven steam cooker. A variety of models can be provided in accordance with the capacity requirements.

| Availability: | |

|---|---|

| Quantity: | |

With our oven steam cooker, you can produce steamed, cooked and roasted products with a high yield and attractive appearance. Uniformity, versatility simplicity and reliability come together while cooking with our oven steam cooker. A variety of models can be provided in accordance with the capacity requirements.

Working Principle

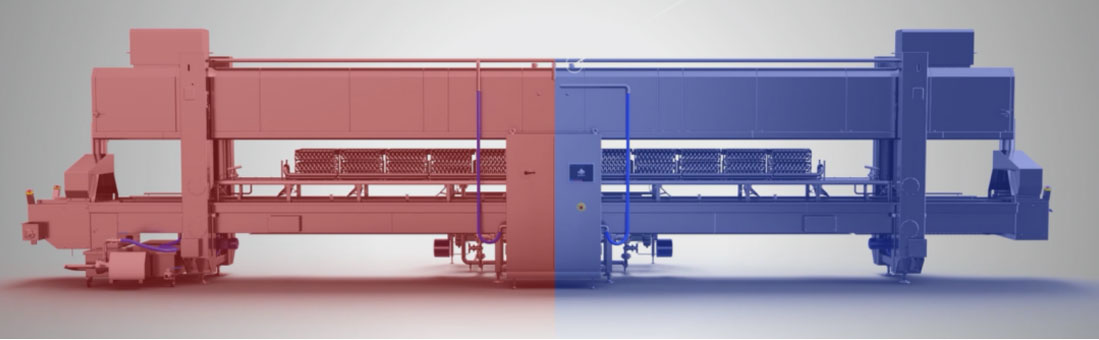

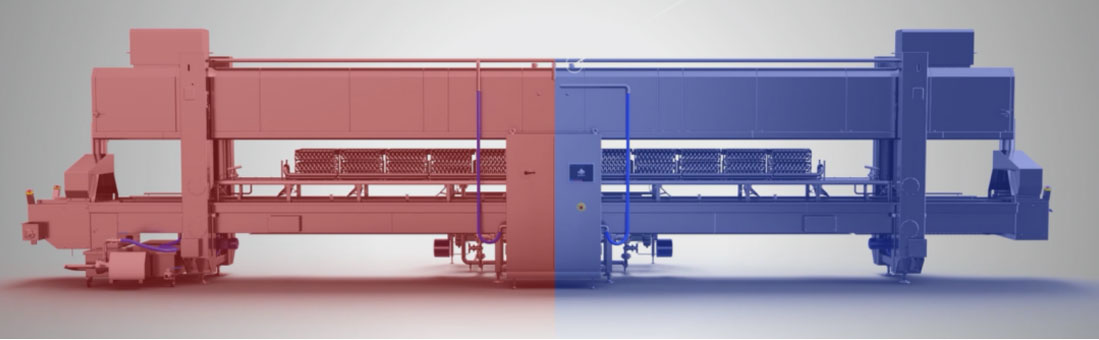

A conveyor transports the products into the oven which consist of two independent zones. The principle is based on a combination of horizontal and vertical airflow ensuring best flexibility for a wide range of applications. A sophisticated air circulation system with air guiding plates optimizes heat distribution to the product. The machine is standard equipped with a double dewpoint control system to optimize product yield and product characteristics. Cooking temperatures can be adjusted to a maximum of 240C. For high temperature applications and sticky products the belt can be dipped into lecithin bath.

• Two independent zones

• Horizontal and vertical airflow

• Double dewpoint control

• Adjustable temperatures

Equipment Performance

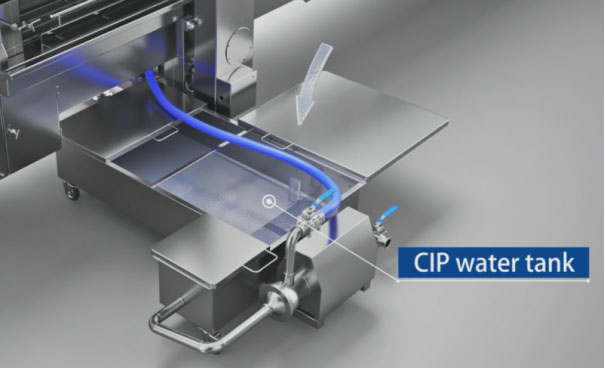

Lowest variation of product color and core temperature over the belt width by combined horizontal and vertical airflow. Maximum uptime, even with most difficult applications, due to a continuous belt wash system. Product sticking to the belt is reduced by the lecithin dip and/ or the optional heavy duty belt wash system. A semi-automatic CIP system ensures shorter cleaning procedures and less down time.

• Lowest variation of product color and core temperature

• Uniform airflow

• Maximum uptime

• Internal Omni-directional cleaning

Product Quality

Two zones in balance with identical but mirror image airflow ensure good separated cooking conditions to control the cooking process. Humidity is controlled by dewpoint per zone individually, the air circulation can be adjusted to support any cooking process imaginable. The high velocity vertical air flow in the middle of the cooking process provides maximum browning and roasting or at lower levels controls crispiness and quality at minimum yield loss. Independent processes per cooking zone provide the flexibility required but with high consistency. A lecithin dip at infeed provides an anti-sticking layer on the belt to reduce product quality issues and ensures longer production runs.

• Separated cooking conditions

• High quality of products

• Browning and roasting

• Consistent production runs

Hygienic Design

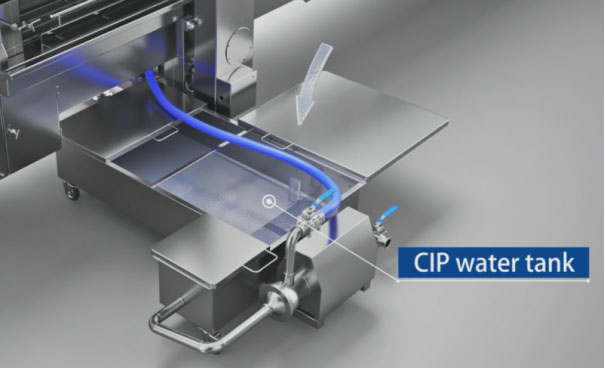

Our hot air steam cooking oven has a semi-automatic CIP system to assist the cleaning process. The hood is lifted automatically for easy inspection and manual post cleaning. The Continuous conveyor belt cleaning system assists maximum cleaning efficiency and maximum uptime.

• Semi-Automatic CIP system (Optional)

• Continuous conveyor belt cleaning system

Safety

The return belt works as a scraper system to remove sediment from the cooking area, avoiding caramelizing and a potential fire hazard. Provide food grade lubrication in the roasting area.

• Sediment removal

• Food grade lubricant

Control Device

The important variables in the cooking process can be controlled, such as cook temperature, dewpoint, circulation speed, cook time. Process variables are stored by menu through our process controls.

•Cooking process control through our process controls

With our oven steam cooker, you can produce steamed, cooked and roasted products with a high yield and attractive appearance. Uniformity, versatility simplicity and reliability come together while cooking with our oven steam cooker. A variety of models can be provided in accordance with the capacity requirements.

Working Principle

A conveyor transports the products into the oven which consist of two independent zones. The principle is based on a combination of horizontal and vertical airflow ensuring best flexibility for a wide range of applications. A sophisticated air circulation system with air guiding plates optimizes heat distribution to the product. The machine is standard equipped with a double dewpoint control system to optimize product yield and product characteristics. Cooking temperatures can be adjusted to a maximum of 240C. For high temperature applications and sticky products the belt can be dipped into lecithin bath.

• Two independent zones

• Horizontal and vertical airflow

• Double dewpoint control

• Adjustable temperatures

Equipment Performance

Lowest variation of product color and core temperature over the belt width by combined horizontal and vertical airflow. Maximum uptime, even with most difficult applications, due to a continuous belt wash system. Product sticking to the belt is reduced by the lecithin dip and/ or the optional heavy duty belt wash system. A semi-automatic CIP system ensures shorter cleaning procedures and less down time.

• Lowest variation of product color and core temperature

• Uniform airflow

• Maximum uptime

• Internal Omni-directional cleaning

Product Quality

Two zones in balance with identical but mirror image airflow ensure good separated cooking conditions to control the cooking process. Humidity is controlled by dewpoint per zone individually, the air circulation can be adjusted to support any cooking process imaginable. The high velocity vertical air flow in the middle of the cooking process provides maximum browning and roasting or at lower levels controls crispiness and quality at minimum yield loss. Independent processes per cooking zone provide the flexibility required but with high consistency. A lecithin dip at infeed provides an anti-sticking layer on the belt to reduce product quality issues and ensures longer production runs.

• Separated cooking conditions

• High quality of products

• Browning and roasting

• Consistent production runs

Hygienic Design

Our hot air steam cooking oven has a semi-automatic CIP system to assist the cleaning process. The hood is lifted automatically for easy inspection and manual post cleaning. The Continuous conveyor belt cleaning system assists maximum cleaning efficiency and maximum uptime.

• Semi-Automatic CIP system (Optional)

• Continuous conveyor belt cleaning system

Safety

The return belt works as a scraper system to remove sediment from the cooking area, avoiding caramelizing and a potential fire hazard. Provide food grade lubrication in the roasting area.

• Sediment removal

• Food grade lubricant

Control Device

The important variables in the cooking process can be controlled, such as cook temperature, dewpoint, circulation speed, cook time. Process variables are stored by menu through our process controls.

•Cooking process control through our process controls