- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

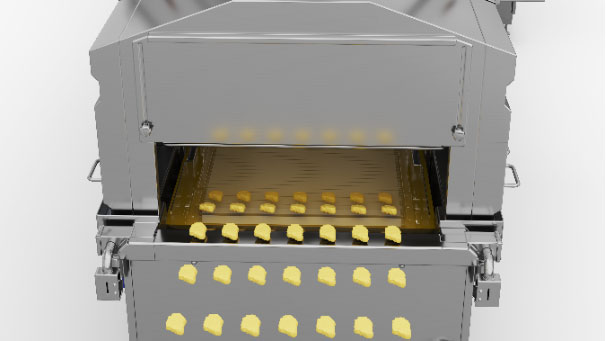

Wolfking electric heating fryer is a modular fryer available in lengths from 4 to 6 meters, and in widths of 650 and 1050 mm. The heat exchanger delivers the highest heating capacity in the industry, and guarantees fast and uniform heating. Wolfking fryer produces a beautifully fried end product with an attractive color, enhanced taste and perfect texture. Wolfking has used all its innovative knowledge of frying in the fryer for the production of low and high volumes of consistent top-quality products. It is suitable for products with all types of coating, varying from crumb up to tempura.

Equipment performance

Wolfking fryer is a modular fryer available in lengths from 4 to 8 meters, and in widths of 450, 650, 800 and 1050 mm. The heat exchanger delivers the highest heating capacity in the industry, and guarantees fast and uniform heating. Wolfking fryer produces a beautifully fried end product with an attractive color, enhanced taste and perfect texture. Wolfking has used all its innovative knowledge of frying in the fryer for the production of low and high volumes of consistent top quality products. It is suitable for products with all types of coating, varying from crumb up to tempura.

Conveyor belt

Some Teflon mesh belt and stainless steel mesh belt convey products through hot oil, can adjust the height of the downward pressure conveyor belt to ensure that a conveyor belt - partly Teflon - transports the products through the heated oil. The hold-down conveyor which can adjusted in height, ensures the products remain immersed. A built-in slotted screen filter removes floating (surface) sediment out of the fryer. the product remains immersed. The built-in slot filter removes floating sediment from the fryer.

Efficient heat exchange

The highly efficient heat exchanger optimizes heat transfer to the oil, enabling a lower thermal oil temperature and therefore lower boiler operating costs.

Hygienic design

The open sanitary design and the open design of heat exchanger tubing optimize access from all angles, simplifying cleaning and maintenance. The fryer features a programmable recirculating Clean-In Place (CIP) system, and its hygienic design with sloped surfaces ensures minimal dirt traps.

Safety

The fryers are easy to clean and maintain as well as safe to operate. Provisions for fire extinguish system.

Control device

• PLC controlled

• Full color touch screen

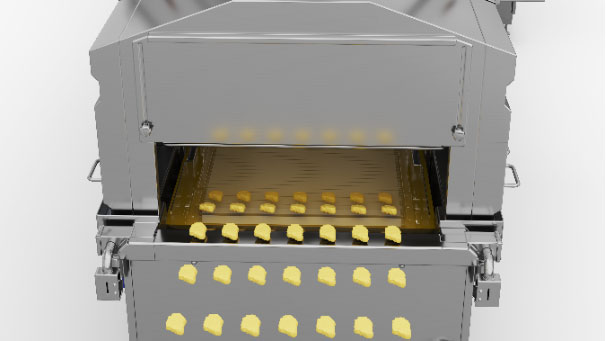

Wolfking electric heating fryer is a modular fryer available in lengths from 4 to 6 meters, and in widths of 650 and 1050 mm. The heat exchanger delivers the highest heating capacity in the industry, and guarantees fast and uniform heating. Wolfking fryer produces a beautifully fried end product with an attractive color, enhanced taste and perfect texture. Wolfking has used all its innovative knowledge of frying in the fryer for the production of low and high volumes of consistent top-quality products. It is suitable for products with all types of coating, varying from crumb up to tempura.

Equipment performance

Wolfking fryer is a modular fryer available in lengths from 4 to 8 meters, and in widths of 450, 650, 800 and 1050 mm. The heat exchanger delivers the highest heating capacity in the industry, and guarantees fast and uniform heating. Wolfking fryer produces a beautifully fried end product with an attractive color, enhanced taste and perfect texture. Wolfking has used all its innovative knowledge of frying in the fryer for the production of low and high volumes of consistent top quality products. It is suitable for products with all types of coating, varying from crumb up to tempura.

Conveyor belt

Some Teflon mesh belt and stainless steel mesh belt convey products through hot oil, can adjust the height of the downward pressure conveyor belt to ensure that a conveyor belt - partly Teflon - transports the products through the heated oil. The hold-down conveyor which can adjusted in height, ensures the products remain immersed. A built-in slotted screen filter removes floating (surface) sediment out of the fryer. the product remains immersed. The built-in slot filter removes floating sediment from the fryer.

Efficient heat exchange

The highly efficient heat exchanger optimizes heat transfer to the oil, enabling a lower thermal oil temperature and therefore lower boiler operating costs.

Hygienic design

The open sanitary design and the open design of heat exchanger tubing optimize access from all angles, simplifying cleaning and maintenance. The fryer features a programmable recirculating Clean-In Place (CIP) system, and its hygienic design with sloped surfaces ensures minimal dirt traps.

Safety

The fryers are easy to clean and maintain as well as safe to operate. Provisions for fire extinguish system.

Control device

• PLC controlled

• Full color touch screen