- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2023-12-04 Origin: Site

On the morning of November 16, 2023, WolfKing foodtech Co., Ltd. officially moved to the new factory. During the celebration ceremony, it was packed with domestic and international distinguished guests from all over the world. They came and brought their best wishes and expectations to WolfKing.

President Mr Sean made a speech about his greatest thanks to all the guests and customers who supported wolfking tech in the past few years. Also a blueprint about upgrading the whole food processing industry with automation and technology is described. Wolfking will evolve and become a well known, reliable and one of the best choices of food processing industry in the future across the world.

The first phase of the new factory covers an area of 12,000 square meters, with a total land area of 45,000 square meters. The factory structure is stable and safe, equipped with complete and advanced processing and manufacturing equipment. The office facility is in line with the world's first-class level.

High-quality products can’t be made without a high-end and excellent foundation. So from conception, and design to construction, all stages of the factory building strictly obey this rule. Wolfking doesn’t only need the guest’s amazing but the better service it can supply.

The company's exhibition hall displays various patents, equipment, processing production lines, and various overall solutions from its inception to the present. Each product has been innovatively designed by engineers and continuously optimized to this day. They all are becoming highly competitive key products in the food industry.

Each brand displayed on the exhibition plate is the outstanding corporate representative who has given full trust to WolfKing and was impressed by WolfKing's quality and service. After many years of hard work, WolfKing finally achieved something through its unremitting efforts and the help of many precious customers.

WolfKing foodtech started with supplying freezing equipment and heating equipment, and slowly entered the track of overall solutions. With key equipment such as spiral oven, tunnel oven, fryer, spiral freezer, plate freezer, tunnel freezer, fluidized bed freezer, and brine shower freezer, we have expanded the service to the following overall factory project: marine aquatic processing production line, land aquatic processing production line, meat processing production line, rice and noodle processing production line, baking processing production line, etc.

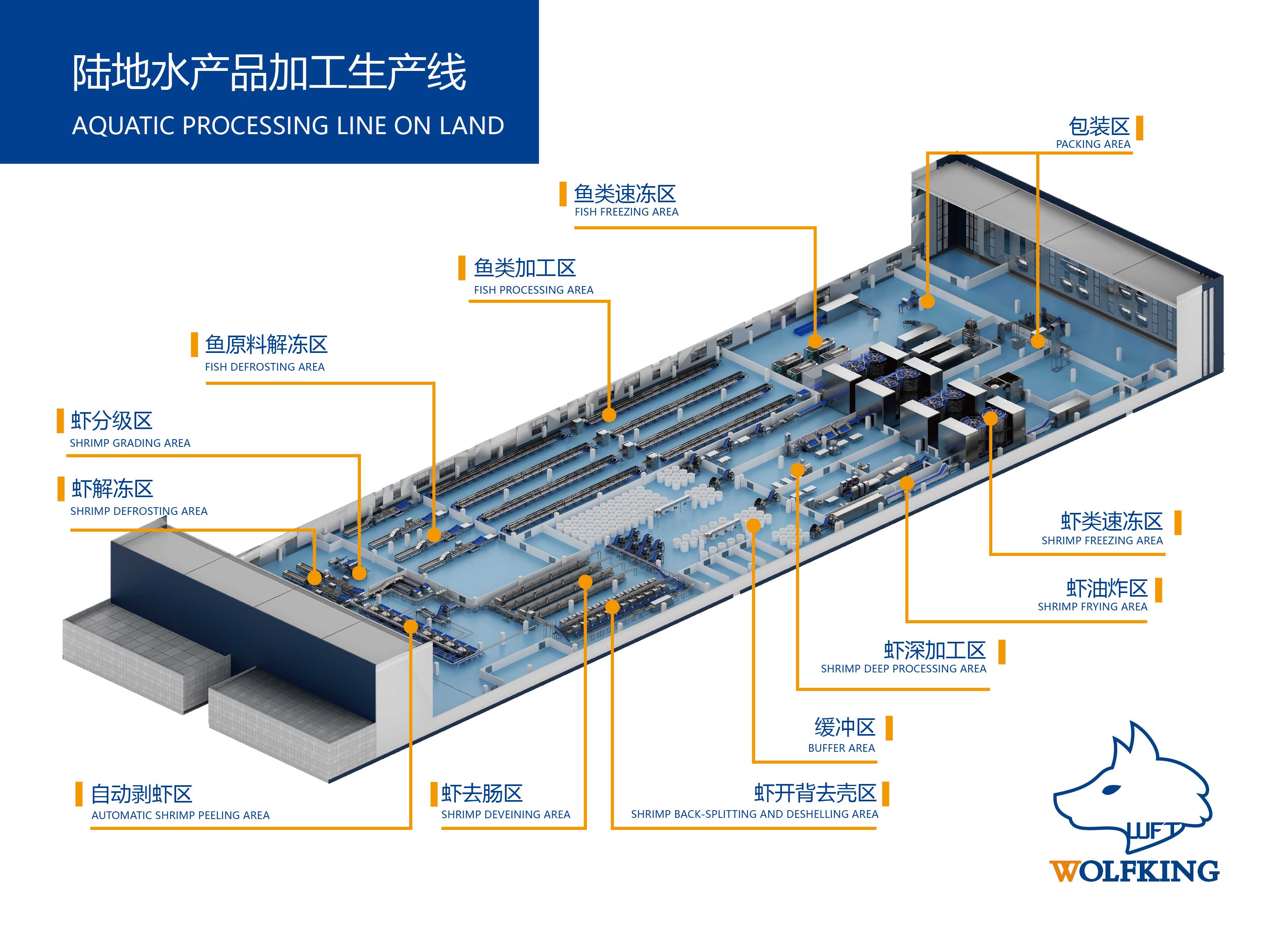

Wolfking foodtech supplies the whole solution for the aquatic processing plant. The main factory is seperated into two zones. One is for shrimp processing and another is for fish processing.

The shrimp processing area covers the shrimp grading, shrimp defrosting, shrimp automatic deshelling, shrimp deveining, shrimp deep processing, shrimp freezing, shrimp packing process. The whole process is conducted by the automatic shrimp prcessing line. With most process runned by our shrimp processing machine, only a few labour needed to take care of the whole processing system. It saves time and human resource cost, at the same time, make peeling process more controllable and hygienic.

The fish line consists of fish defrosting, fish processing, fish freezing, fish packing process. This line may be high customized by the needs of customizer because of various kinds of fishes.

Aquatic Processing Line On Ship

Rice Flour Processing Line

Baking Processing Line

Meat Processing Line

The equipment manufactured by wolfking foodtech is working day and night in various industries. wolfking has entered rice flour, poultry, prepared food, hot pot ingredient, fruit&vegetable, ice cream, bakery, aquatic product, ocean fishing industries. Wolfking will payback the customers’ trust to the wolfking team with better service, product and solutions.

Below are some of the brands that has established cooperation with wolfking